Out of the top ten current global issues, climate change and pollution top the list. These issues have brought about adverse effects on our climate, health and communities. This study aims to investigate the structural performance of sawdust ash blended steel slag aggregate concrete and modelling their structural properties using a multivariate interpolation method. In order to achieve this, the physical properties, physio-chemical, chemical composition, mechanical properties tests were conducted. The result revealed that sawdust ash is classified as a class C type pozzolan having a total of 61.59% combined percentage masses of silica, alumina and ferric oxides, while steel slag aggregate is classified as poorly graded. The composite concrete recorded higher density, compressive and split tensile strengths when compared with normal concrete cured in potable water. The results revealed that normal concrete with normal aggregate is more durable than sawdust ash blended steel slag aggregate (composite) concrete when cured in an aggressive environment. The developed models were found to agree strongly with the experimental data, with an outstanding correlation level. This research has led to the creation of high strength pozzolan blended steel slag aggregate concrete, thus improving waste management, reduction in environmental pollution and \(CO_2\) gas emission.

In December 2018, the world’s population was estimated to be 7.7 billion. Nigeria ranked number seven and was estimated to have an equivalent of 2.57% of the world population (Worldometers, 2018). Nigeria, being the most populous African country, has an urban population of 51.0% of its population and this has a direct link to the demands on food, clothing and shelters [1]. Urban cities like Lagos, Ibadan, Warri, Kano, Ibadan, Kaduna, Abuja, Calabar, etc, are housing a large number of people and due to their landmass, there are high demands on taller buildings in order to accommodate the population [2]. In most developing countries like Nigeria, Portland cement as a water-based binder in concrete is the most utilized construction material [3] and is not an environmentally friendly material because its production and usage emit over 5% of the total \(CO_2\) anthropogenic emissions [4]. In 2015, the Fredonia group projected that in 2019 the global demand for cement would reach 5.2 billion metric tonnes. The cost of construction continues to increase globally, especially in Nigeria where construction cost is one of the highest [5].

According to the National Ready Mixed Concrete Association, in mix designs, the binder content is largely a function of the amounts of carbon dioxide \(CO_2\) embodied in concrete. For every ton of cement manufactured, over half a ton of \(CO_2\) emissions is on the loose into the atmosphere which makes cement the third-largest \(CO_2\) producer in the world [6]. The mining process of aggregates (fine and coarse) has an adverse effect on the ecosystem around the operation areas [7]. Quarry activities have a major impacton the environment like engineering impact (chemical spills, noise, vibrations, erosion, dust, loss of habitat, etc), cascading impacts (removal of rock) and geomorphic impact [8].

Nigerian Environmental Society (NES), said that Nigeria as a nation generates over 60 million tonnes of waste annually with less than 10% waste management capacity [9]. One of the goals of sustainable construction is the reduction of cement usage in the production of concrete. Also, the reusability of industrial and agricultural waste materials in concrete production offers environmental gains and the preservation of natural resources [10].

Sawdust, an industrial waste generated from the timber industry, produced as wood chippings or loose particles from sawing of timber into desired or standard usage sizes [11]. Due to the nation’s poor waste management techniques, sawdust poses a nuisance to the health of citizens and the environment. Steel-slag, a by-product of the steel, produced when scrap metals and irons are liquefied together with fluxes under oxidizing conditions by injecting an enormous amount of air or oxygen [12]. Cordeiro et al., [13] proposed the usage of pozzolanic and blended cement to reduce the use of Portland cement in concrete production. Abdullah et al., [14] supported the proposition by saying blended cement and concrete incorporated with pozzolanic materials have created an innovative solution for producing concrete with savings in energy, improvement in certain properties of hardened and fresh concrete (like extensibility, workability, heat of hydration, resistance from sulphate attack, and other environmental considerations, by decreasing \(CO_2\) emissions). Raheem et al., [15], investigated saw dust ash as a partial replacement for cement in concrete and they observed that the compressive strength decreased with increasing SDA replacement at early stages but improves significantly with curing age. It was concluded that 5% SDA substitution is adequate to enjoy the maximum benefit of strength gain. The inclusion of SDA into the concrete matrix causes little expansion due to low calcium content [3], saturating the cement mix with oxides such as \(K_2O\) and \(MgO\) in SDA which form composites that may inhibit the formation of strength-giving calcium silicate hydrates from cement hydration [16] and the optimum replacement level of 10% by volume SDA can be used to partially replace cement [17,18,19].

The usage of waste aggregates such as steel slag can help reduce the dependence on the natural rock (granite), hence preserving our natural resources, recycling and optimum utilization of by-products for economic, environmental and construction aims [20]. The investigation of the compressive strength of steel slag aggregate concrete by many researchers shows an increase in strength up to 75% replacement and a further increase in steel slag resulted in a decline in strength [20,21]. Thangaselvi [22] stated that the improvement in strength may be due to shape, size and surface texture of steel slag aggregates, which provide better bonding between the particles and cement paste. Awoyera et al., [23] studied the performance of steel slag aggregate concrete with varied water-cement ratio, observing an increase in strength gain due to steel slag aggregate inclusion and concluded that a rapid strength development can be obtained in concrete by reducing the water-cement ratio. Presently, the desire to drastically reduce \(CO_2\) emissions, high demand for cement and its energy consumption and the dependence on other natural resources in the production of high performing concrete have led to the search for innovative binders and aggregates with the view to produce high strength and more durable concrete. These materials range from industrial bye products like silica fume, steel slag, blast furnace slag and fly ash to agriculture wastes like sugarcane bagasse ash, rice husk ash, sawdust ash, and com cub ash. Therefore, it is valuable to study the performance of concrete having a certain percentage of sawdust ash as binder and steel slag aggregate as normal coarse aggregate regarding the strength and durability properties of concrete. Hence, exploring innovative materials incorporated into concrete production is of great significance to the civil engineers for sustainable development, sustainable concrete production, sustainable construction and hence, sustainable development.

| Sample | Sample Description | Chemical Constituents | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| \(SiO_2\) | \(Al_2O_3\) | \(Fe_2O_3\) | \(CaO\) | \(MgO\) | \(Na_2O\) | \(K_2O\) | \(CaCO_3\) | \(SO_3\) | \(P_2O_5\) | \(L.O.I\) | Total \(SiO_2\) +\(Al_2O_3\) | Total \(SiO_3\)+ \(Al_2O_3\) +\(Fe_2O_3\) | ||

| Cement | Grey Powdery Solid | 2.85 | 5.26 | 1.35 | 64.12 | 2.72 | 0.76 | 0.48 | 11.45 | 1.2 | 0.3 | 0.1 | 8.11 | 9.46 |

| SDA | Grey Powdery Solid | 31.29 | 27.38 | 2.29 | 10.72 | 9.2 | 6.63 | 10.45 | 19.14 | 0 | 0.5 | 2.9 | 59.3 | 61.59 |

| Parameters | UNILAG Tap water | UNILAG Lagoon water | WHO Standard | BS Standard (BS 3148:1980) | Nigeria Standard |

|---|---|---|---|---|---|

| ph | 6.4 | 6.3 | 6.5-8.5 | 6.0-8.0 | 6.5-8.5 |

| Temperature(\(^oC\)) | 27.4 | 27.5 | Ambient | Not mentioned | Not mentioned |

| Salinity \((ppm)\) | 72 | 460 | Not mentioned | Not mentioned | Not mentioned |

| Conductivity (\(us cm^{-1}\)) | 170 | 340 | 750 | Not mentioned | 1000 |

| TDS \((mg/l)\) | 125 | 245 | 1000 | 2000 | 500 |

| Chloride \((mg/l)\) | 64 | 140 | 250 | 500 | 250 |

| Calcium Hardness \((mg/l)\) | 48 | 64 | Not mentioned | Not mentioned | 150 |

| Total hardness \((mg/l)\) | 60 | 108 | 100 | Not mentioned | Not mentioned |

| Acidity \((mg/l)\) | 12 | 16 | Not mentioned | Not mentioned | Not mentioned |

| Alkalinity \((mg/l)\) | 20 | 96 | 100 | 1000 | Not mentioned |

| Sulphates \((mg/l)\) | 60 | 90 | 250 | 1000 | 100 |

| Colour \((pcu)\) | 179 | 792 | 15 | Not mentioned | Not mentioned |

| Calcium \((mg/l)\) | 7.5 | 8.86 | 200 | Not mentioned | Not mentioned |

| Manganese \((mg/l)\) | 0.32 | 0.22 | 0.5 | Not mentioned | 0.2 |

| Copper \((mg/l)\) | 0.54 | 0.54 | 2 | Not mentioned | 1 |

| Zinc \((mg/l)\) | 3.76 | 5.62 | 3-5 | Not mentioned | 3-5 |

| Lead \((mg/l)\) | 0.12 | ND | 0.01 | Not mentioned | 0.01 |

| Iron \((mg/l)\) | 14.98 | 108.3 | 0.3 | Not mentioned | 0.3 |

| Cadmium \((mg/l)\) | 0.04 | 0.21 | 0.003 | Not mentioned | 0.003 |

| Physical properties | Cement | Saw Dust Ash (SDA) | Sand | Granite | Steel Slag |

|---|---|---|---|---|---|

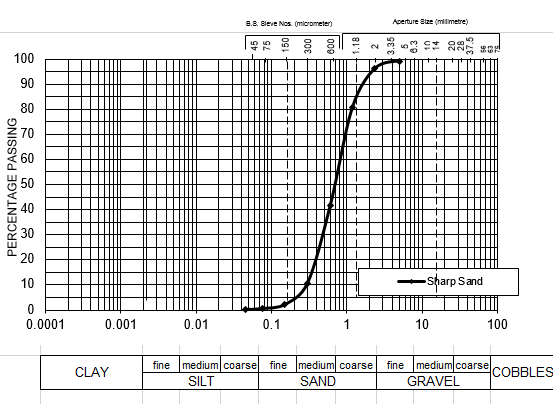

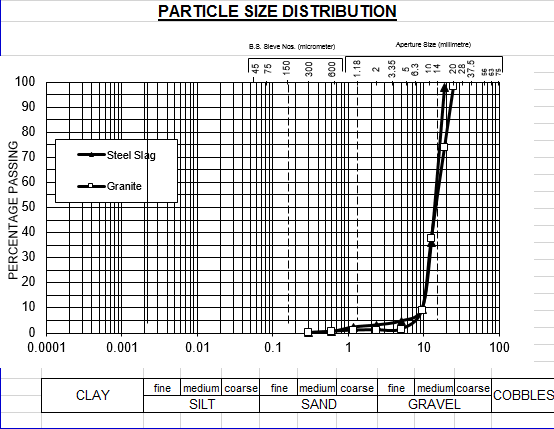

| Coefficient of Uniformity \((C_u)\) | – | – | 2.67 | 1.7 | 1.6 |

| Coefficient of Curvature \((C_c)\) | – | – | 1.04 | 0.99 | 1.06 |

| microns sieve) (Moisture Content (Dry Density \((kg/m^3)\) | 521.01 | 129.28 | 126.13 | 692.66 | 1098.13 |

| Bulk Density \((kg/m^3)\) | 1015.96 | 511.96 | 1186.90 | 1295.27 | 1229.91 |

| Specific Gravity | 2.90 | 2.11 | 2.50 | 2.85 | 2.64 |

The values of dry and bulk density for the concrete constituents are within the standard ranges (BS EN 197-1:2011, BS 12:1996), having steel slag classified as normal weight aggregate according to ASTM C330. The steel slag aggregate recorded a significant increase in moisture content which can be attributed to the presence of voids. The water absorption values for the coarse aggregates are within the standard range of 0.1-2.0%. The results of the aggregate impact value test, aggregate crushing value test and Los Angeles abrasion test revealed that granite has greater resistance, stronger and higher toughness when compared to steel slag.

The results of the slump test and compacting factor test for steel slag aggregate-based concrete are presented in Table 4. From the Table 4, a stiff plastic was observed having no separation of coarse aggregate particles from the mortar matrix during placement. After placement, no notable bleeding was found for fresh concrete.

| Control | Composite | |

|---|---|---|

| Slump (mm) | 30 | 20 |

| Compacting factor | 0.834 | 0.825 |

| Degree of Workability | Low | Low |

| Stiff plastic | Stiff plastic |

The concrete without sawdust ash and steel slag aggregate recorded higher workability compared to the composite mix having sawdust ash and steel slag aggregate. The reduced values of a slump and compacting factor for the composite can be attributed to the presence of water-absorbing properties of sawdust ash and steel slag which left little amounts of water in the mortar available for hydration in the concrete matrix [17,24].

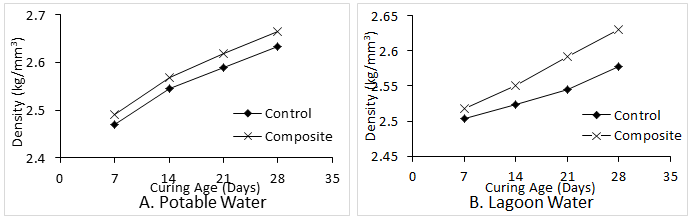

The results of the density of sawdust ash blended steel slag aggregate concrete is presented in Figure 3.

Figure 3 shows the relationship between the control specimen and the composite for two different curing media. The density of concrete increases with an increase in the curing age. A slower rate of strength development was observed for control and composite samples cured in lagoon water due to the presence of some chemicals above the standard level of concentration. Lower densities were recorded for specimens cured in lagoon water. The density at 28 days for the control specimen was about \(2640kg/mm^3\) and \(2660kg/mm^3\) for the composite. The value of the density of sawdust ash blended steel slag aggregate concrete (composite) was 1.16% higher than the normal concrete with granite (control). The rate of deterioration on the density of the control specimens was 1.16% and 1.26% for composite at 28 days when relating the potable water curing to the lagoon water curing. In both curing media, the composite specimen performed better than the control due to the presence of steel slag aggregate which caused more increase in a unit weight of concrete [25]. The high-density values observed in composite concrete can be attributed to the high dry density of steel slag compared with limestone. Also, the nature of SDA as a good absorbent of moisture contributed to the increase in density [15].

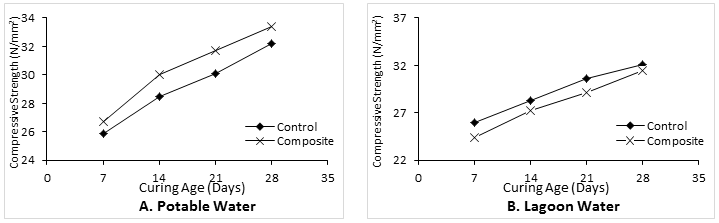

From Figure 4, the influence of curing age on the compressive strength of the control and composite specimens was illustrated and it was observed that as the curing age increases, the compressive strength increases for both samples. The compressive strength of the composite was observed to be higher than the control specimens in potable water curing and vice versa in lagoon curing. This was mainly due to cement hydration and the build-up of hydration products which filled up the available pore spaces inside the concrete matrix resulting in strength performance improvement [23]. The rate of internal strength development in the composite depends on the pozzolanic activities of minerals present in the sawdust ash and steel slag as well as their differences in the particle shape, surface texture and zonal composition of aggregates [26,27].

The strength gain in the control increased with increase in curing age of 10.03% of 7 days to 14 days curing up to 24.64% gain at 28 days curing in potable water which was observed higher than the specimens cured in lagoon water having 9.13% at 14 days to 23.91% at 28 days. A trend opposite to that of the potable water was observed in the lagoon water curing as the composite having a higher strength gain of 28.96% to that of 24.79% of the control at 28 days. The decrease in the strength of the composite can be attributed to the presence of chloride and sulphate ion which leads to expansion and weakens the bonds between the aggregate and the paste. Therefore, the development of crack formation within the concrete mass together with leaching action of the newly formed compounds would resulting the reduction of the strength. Nevertheless, the swift gain in strength for specimens cured in lagoon water when compared to potable water is due to the quickening effects of some of the chemical compounds present in the curing medium.

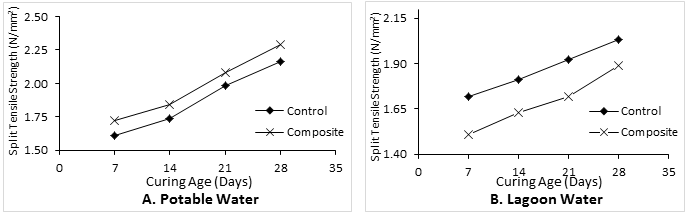

The results of the split tensile test have been analysed and presented in Figure 5. These figures clearly demonstrate that the composite performs better in potable water than in lagoon water curing when compared with its control specimens. In the case of potable water curing, composite shows higher strength than control having \(2.29N/mm^2\) to \(2.16 N/mm^2\) at 28 days curing age.

In lagoon water curing medium, the split tensile strength for 28 days exposure period is \(2.03N/mm^2\) for control and \(1.89N/mm^2\) for composite. The test reveals that the split tensile strength of both the control and composite is greatly affected by the curing medium and the curing age. From Figure 5, the relationship between relative strength and curing ages or exposure periods for different curing environment was presented. As observed, the strength gain with respect to potable water is 8.07%, 23.04% and 34.16% as the curing age increases for control and 6.98%, 20.93% and 33.14% for composite whereas for lagoon water curing slower strength gains were observed from 5.23% to 18.02% for control while 7.95% to 25.17% for composite at 14 and 28 days respectively. The reason for the lower performance of composite in lagoon water curing is due to expansive materials developed as a result of reactions formed during hydration causing microcracks that weaken the bond between the hydrated products and aggregate particles [28]. Thus, the concrete loses its strength and failure occurs.

| Curing Medium | Curing Age | Control | Composite | ||||

|---|---|---|---|---|---|---|---|

| Exp. | MVI Models | Perc. Diff. | Exp. | MVI Models | Perc. Diff. | ||

| Normal Curing | 7 | 2.470123 | 2.470000008 | 0.004998 | 2.4908642 | 2.489999996 | 0.0346995 |

| 14 | 2.545185 | 2.559000008 | -0.54278 | 2.56888889 | 2.569999992 | -0.04325 | |

| 21 | 2.58963 | 2.589000003 | 0.024313 | 2.61925926 | 2.619999984 | -0.02828 | |

| 28 | 2.634074 | 2.630000038 | 0.154667 | 2.66469136 | 2.669999997 | -0.19922 | |

| Lagnoon Curing | 7 | 2.503704 | 2.499999997 | 0.147929 | 2.21851852 | 2.520000007 | -0.05882 |

| 14 | 2.511882 | 2.51999999 | -0.32319 | 2.55111111 | 2.550000016 | 0.043553 | |

| 21 | 2.545185 | 2.549999981 | -0.18917 | 2.59259259 | 2.590000029 | 0.099999 | |

| 28 | 2.577778 | 2.57999997 | -0.08621 | 2.63111111 | 2.630000043 | 0.042228 | |

| Curing Medium | Curing Age | Control | Composite | ||||

|---|---|---|---|---|---|---|---|

| Exp. | MVI Models | Perc. Diff. | Exp. | MVI Models | Perc. Diff. | ||

| Normal Curing | 7 | 25.8518519 | 25.85000004 | 0.00716317 | 26.7400000 | 26.74000006 | -2.2438E-07 |

| 14 | 28.4444444 | 28.44000011 | 0.01562461 | 30.0000000 | 30.00000014 | -4.6667E-07 | |

| 21 | 30.0740741 | 30.07000021 | 0.0135461 | 31.7400000 | 31.74000026 | -8.1916E-07 | |

| 28 | 32.2222222 | 32.22000038 | 0.00689537 | 33.3700000 | 33.37000046 | -1.3785E-06 | |

| Lagnoon Curing | 7 | 25.9300000 | 25.92999996 | 1.5426E-07 | 24.4100000 | 24.41000003 | -1.229E-07 |

| 14 | 28.3000000 | 28.29999991 | 3.1802E-07 | 27.2592593 | 27.26000004 | -0.00271754 | |

| 21 | 30.5800000 | 30.57999988 | 3.9241E-07 | 29.1851852 | 29.19000006 | -0.01649767 | |

| 28 | 32.1300000 | 32.12999986 | 4.3573E-07 | 31.4800000 | 31.48000008 | -2.5413E-07 | |

| Curing Medium | Curing Age | Control | Composite | ||||

|---|---|---|---|---|---|---|---|

| Exp. | MVI Models | Perc. Diff. | Exp. | MVI Models | Perc. Diff. | ||

| Normal Curing | 7 | 1.61 | 1.610000002 | -1.2E-07 | 1.72 | 1.719999998 | 1.16E-07 |

| 14 | 1.74 | 1.740000002 | -1.1E-07 | 1.84 | 1.839999999 | 5.43E-08 | |

| 21 | 1.981 | 1.979999999 | 0.05048 | 2.08 | 2.079999996 | 1.92E-07 | |

| 28 | 2.16 | 59999996 | -2.8E+09 | 2.29 | 2.289999999 | 3.06E-08 | |

| Lagnoon Curing | 7 | 1.72 | 1.719999997 | 1.74E-07 | 1.51 | 1.510000001 | -6.6E-08 |

| 14 | 1.81 | 1.809999995 | 2.76E-07 | 1.63 | 1.629999998 | 1.23E-07 | |

| 21 | 1.92 | 1.919999993 | 3.65E-07 | 1.72 | 29.19000006 | 2.91E-07 | |

| 28 | 2.03 | 2.029999991 | 4.43E-07 | 1.89 | 1.88999999 | 5.29E-07 | |