Although synthetic dyes are commonly used, natural dyes are still being utilized and used to improve their intrinsic aesthetic properties as the main material for the body’s beauty. For example, research results have shown that henna plant leaves comprise dye together with other additives. This provides a hint that if color from henna is properly studied, it can be used not only as body decoration but may also have fiber-substrates affinity. This paper explores the dyeing possibility-the ability to dye and the fastness qualities of henna dye extracted from henna leaves on cotton fabric compared to reactive dyeing using the same dyeing technique as reactive dyeing. Also, color fastness tests have been performed according to the ISO test methods. The implications of henna dye have been shown to have poor to moderate dyeing capability towards cotton fabrics as opposed to the reactive dyes when henna dyeing is accompanied by reactive dyeing. Similarly, henna dye demonstrated satisfactory properties of fastness as opposed to reactive dye. For henna dye with 50% shade, it gives an outstanding color tone with a good level of coloration. Taken into account the ability to dye and the fastness of color, the dyeing of matured henna leaves is equally advantageous to the dyeing of cotton fabrics.

The country such as Bangladesh has very much potential in the textile sector. In the garments sectors of our country, mainly woven and knit fabrics are used. Nowadays, Bangladesh has attained the top most leading position in the garments business. To help the garment industry, a large number of the other textile sectors have been developed and there will be more in the near future [1].

However, the textile industry includes many sections with operating operations, one of which is the dyeing industry for coloring fabrics. The textile dyeing industry’s contribution as a whole is essential to make fabrics with different shades. For this reason, to produce different shades on fabrics, textile dyes play a significant role. Moreover, textile dyes are a potentially important component of the industry as a whole. As Bangladesh is abundant in natural resources, the production of dyes in Bangladesh is relatively simple and easier. The textile dyes industry is booming in Bangladesh because of the textile industry’s growth in the emerging economies [2]. Additionally, it is estimated that the Textile Dyes Market, which was accounted for USD 7.34 billion in 2017, will increase to USD 9.82 billion by 2022 [3]. That’s why fabric dyeing processing has become the talked of topics today in our country.

In textile manufacturing, dyes are derived from two primary sources: natural dyes and synthetic dyes. Natural dyes can be characterized as organic materials that have the potential to add color to any substance for that they may have had an affinity. Natural dyes are environmentally friendly and very compliant with the environment, as they can be derived either from plants, animals, or minerals. They have beauty, depth of color, and less bright than synthetic dyes, but these natural color components were sustainable and biodegradable [4,5,6,7].

Compared to natural dyes, synthetic dyes have become commonly used due to cheaper costs [7,8] and a wide variety of vibrant colors with dramatically enhanced color fastness properties [6,9]. For example, reactive dyes have a chromophore group that is responsible for reacting with the substrate. These dyes have good color fastness properties due to the covalent bond established while dyeing [9,10]. The use of synthetic dyes became more appropriate in the food, cosmetic, and textile industry. Although most of the synthetic dyes were prepared from chemical compounds recently, those were not always welcoming for the human. However, all the natural dyes were suitable for humans, and these dyes did not harm the skin [11,12,13]. Furthermore, they have reduced toxicity and adverse reactions than that of synthetic dyes. Needless to say, many synthetic dyes have been forbidden since they induce allergy or carcinogenicity like symptoms.

Due to increased consciousness of the therapeutic properties of colors, global demand for natural dyes is of significant concern today. Though natural dyes applied in food are evaluated for protection, the details are not available for other natural dyes used in craft dyeing and possibly for boarder use. There is a reason to suppose that natural consumables are better than manufactured goods because they naturally have been made. If they are more commonly and commercially used, the safety of natural dyes must be demonstrated [5]. With respect to environmental considerations, the use of renewable non toxic and gentle natural colors needs to be reconsidered. Environment friendly natural dyes are a well-known phenomenon which produces innovative ideas. This is because it may be a viable choice for our dyeing requirements.

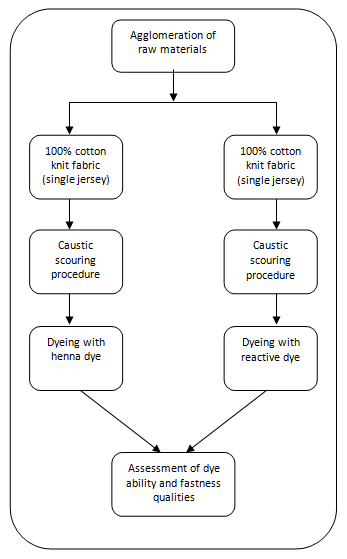

Highlighting certain of such problems, the purpose of this study was to determine the dye ability of henna dye towards cotton fabrics in contrast with the reactive dye using reactive dyeing technique.

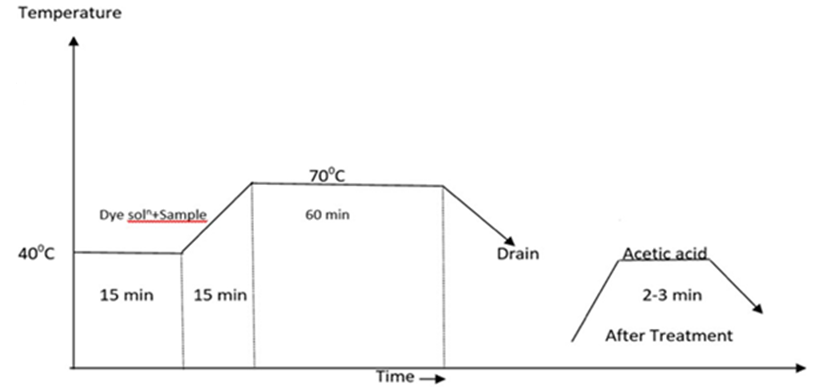

Process: For 5% and 10% shade, 5% and 10% of dyestuffs, i.e., henna dye and reactive dye, has been used. Moreover, 10 gram per liter of glauber salt, 5 gram per liter of Sodium Carbonate, 2 gram per liter of Leveling Agent, 2 gram per liter of Sequestering Agent, 1 gram per liter of Wetting Agent, temperature \(70^{o}C\), time 60 minutes, 20 gm of fabric weight, and 1:30 of Materials to Liquor ratio were used. Firstly, samples and stock solutions were prepared according to the recipe. The required amounts were then taken from the stock solution by burette and measuring cylinder into an open bath. The bath was placed over an oven and stirred continuously. A thermometer was used to measure and control the temperature of the dye bath. When the temperature reached \(40^{o}C\), the soaked and squeezed sample was given to the bath with continuous stirring. After that, the temperature rose to \(70^{o}C\) within 15 minutes and maintained the temperature for 60 minutes. Then the fabric sample was taken out of the bath and rinsed with cold water. To perform after treatment, the washed sample was treated with 1 gram per liter of acetic acid at \(40^{o}C\) for 2-3 min to remove unfixed dye molecules from the fabric surface. In an oven dryer, samples are dried by hot air.

Furthermore, for the alkaline solution, 5 gram per liter of sodium chloride, 2.5 gram per liter of disodium hydrogen phosphate dehydrate, and 0.5 gram per liter of L-Histidine monohydrochloride monohydrate were used. Moreover, \(10cm \times 4cm\) of sample size and \(10cm \times 4cm\) of multi-fiber size were used at \(38^{o}C\) for 4 hours 5 minutes to operate the test. The solution’s pH value was 8.0 that were maintained entirely in the perspiration (alkaline) test. The graphical representation of dyeing curve is given in Figure 4.

From Table 1, it can say that the result of rubbing fastness to dry values of the cotton fabric dyed with henna dye was as same as the cotton fabric dyed with reactive dye, which was shown excellent results. Besides, it can be said that the result of rubbing fastness to wet values of the cotton fabric dyed with henna dye was shown very good results for 5% and 10% shade. Conversely, the result of rubbing fastness to wet values of the cotton fabric dyed with reactive dye was shown good and fair results for 5% and 10% shade, respectively. Hence, from the above discussion, we can say that in comparison with the cotton fabric dyed with reactive dye specimens, henna dye treated cotton fabrics deliver greater values for 5% and 10% shade.

| Dye Name | % of Shade | Type | Result |

|---|---|---|---|

| Henna | 5.0% | Dry | 5 |

| Wet | 4/5 | ||

| 10.0% | Dry | 5 | |

| Wet | 4/5 | ||

| Reactive | 0.5% | Dry | 5 |

| Wet | 4 | ||

| 10.0% | Dry | 5 | |

| Wet | 3 |

From Table 2, Color fastness to wash demonstrates the effects in terms of color staining. These findings indicate that the wash materials vary in the cotton fabric dyed with reactive dye specimens and the cotton fabric dyed with henna dye specimens depending on the nature of the color’s fastness. Yet, henna dye treated cotton fabrics showed more affinity towards protein fiber than cellulosic fiber, understood from the multi-fiber grading in wash fastness.

| % of Dye | Color Staining | Grade |

|---|---|---|

| 5% Reactive | Cotton | 4/5 |

| Nylon | 5 | |

| Polyester | 5 | |

| Acrylic | 5 | |

| Wool | 3 | |

| 55 % Henna | Cotton | 4/5 |

| Nylon | 5 | |

| Polyester | 5 | |

| Acrylic | 5 | |

| Wool | 3/4 |

From Table 3, it has been seen that caustic soda-treated fabric with reactive dye has been shown lower values than that of henna dye since the henna dye is more responsive to cotton fabric binding.

| Dye Name | % of Shade | Type | Result |

|---|---|---|---|

| Henna | 5.0% | Dry | 5 |

| Wet | 4/5 | ||

| 10.0% | Dry | 5 | |

| Wet | 4/5 | ||

| Reactive | 0.5% | Dry | 5 |

| Wet | 4 | ||

| 10.0% | Dry | 5 | |

| Wet | 3 |