Urbanization and soil degradation have placed significant pressure on agricultural sustainability and food security, prompting the exploration of alternatives to soil. The potential of corncob as soilless substrate, an innovative growing media for sustainable urban agriculture, has been preliminary established. Hence, this study investigated the design-related properties of corncob necessary for developing crusher for producing corncob substrate using standard methods. Corncobs from yellow and white corn varieties were used for the study at five moisture levels (9.71, 11.01, 14.29, 17.58 and 21.87% w.b). The results indicate that moisture content rise increased the major axes, angle of repose, surface area and static coefficient of friction. Sphericity decreased for yellow corncob from 0.50 to 0.47 but increased for white corncob from 0.63 to 0.65. Solid and bulk densities decreased: yellow corncob from 0.365 to 0.290 g/cm³ and 0.325 to 0.225 g/cm³, respectively; white corncob from 0.395 to 0.340 g/cm³ and 0.345 to 0.270 g/cm³, respectively. Rupture strengths decreased from 1.12 to 0.80 N/mm² and 1.12 to 0.80 N/mm² for yellow and white corncobs, respectively. Valorization of corncob will create new economic opportunities and give farmers more value for their corn. Hence, this work is pivotal in achieving that with the empirical data provided for developing a corncob crusher for soilless substrate production.

Corn (Zea mays) led the world grain production in 2024 with 1253.73 million metric tons [1]. Apart from the rich nutritious contents of corn, the variety of delicacies it provides endeared it to many households. Corn can be processed into various types of products such as cornmeal, grits, starch, flour, tortillas, snacks, and breakfast cereals [2]. It is a staple food in many parts of the world. Corn seeds are crushed to produce animal feeds and biofuel, while the stalks are used as fodder for feeding livestock. USA and China dominate industrial consumption of corn, and this is because of increasing demand for animal feed and alternative energy using plant feedstock [3]. It is also a valuable raw material for manufacturing industries [4]. Corn is one the most important cereal crops produced and consumed in Nigeria [5]. Nigeria produces over 12 million metric tonnes of corn annually [6, 7]. A ton of shelled corn generates approximately 180 kg of cobs [8]. Nigeria produces about 2.16 metric tonnes of corncob annually. This bioresource is unutilized and wasted in Nigeria, except in rural communities where farmers use dried corncobs as heat source for cooking food and roasting meat. Corncob is an agricultural waste product from corn [9]. Heat, electricity, gas and liquid fuels, and a wide range of chemical compounds like furfural, xylitol, and activated carbon can all be produced from corncobs [10].

Soil, the most available growth medium for plants, is facing many serious challenges in Nigeria. Some of these challenges include urbanization, dessert encroachment, over-utilization, oil pollution, degradation, erosion and poor soil remediation [11– 13]. In view of this, alternative agricultural waste that can replace soil should be explored. Corncob is one of the available agricultural wastes that can be used as soilless substrate for growing crops. It will provide anchorage, nutrients, air, water, etc. for successful plant growth. On the other hand, engineering properties of agricultural products are those properties that guide engineers in designing agricultural equipment like crushing machines. Crushers are categorized as impact or compressive based on the type of applied force [14]. To design any of these crushers for corncob, determination of the engineering properties of corncob is a prerequisite. Researchers have described these properties as valuable data to engineers, food scientists and processors towards design of efficient machines, processes and equipment in agriculture [15, 16]. The importance of these properties has led researchers to determine them for various crop materials [17– 26]. Evaluating these properties as a function of moisture content and variety is very important [22, 23, 27– 30]. The effect of varieties and moisture content on mechanical properties of corn, and the properties of maize kernel and pedicel have been studied [31, 32]. Apart from the work of Zou et al. [33] on the microstructure effects on the mechanical properties of corncob, there is no literature on the effects of variety or moisture content on the engineering properties of corncob till date.

Considering the potential of corncob as substrate for growing crops, there is a need to study the engineering properties to generate empirical data that will be used to design a crusher for corncob. Therefore, the aim of this work is to determine the properties of two varieties of corncob as influenced by moisture for the development of an efficient corncob crusher.

Two varieties of sweet corn (white and yellow) used in this research were procured at Ndoro Market in Ikwuano, Abia State, Nigeria. The corn kernels were manually shelled from the cobs. The cobs were carefully separated and kept in labeled containers to avoid mixing them up.

The moisture content and sample conditioning were done using the method described by Arjun et al. [34]. This method involved drying samples at 105 \(\mathrm{\pm}\) 1\(\mathrm{{}^\circ}\)C for 24 h using an air-ventilated oven (Memmert ULE 500, Germany), and then adding calculated amount of water to vary samples moisture content.

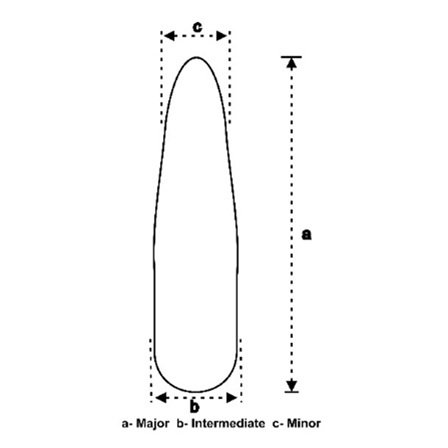

The three principal axes (Figure 1), major axis (a), intermediate axis (b) and minor axis (c) at each moisture level were measured using a vernier caliper (Mitutoyo, Japan) with an accuracy of 0.01 mm. The arithmetic mean diameter D\({}_{a}\) and geometric mean diameter D\({}_{g}\), sphericity, and surface area, and volume were calculated by using Eqs. (1) to (4) of Table 1.

| Property | Symbol | Equation | Equation no. | Reference |

|---|---|---|---|---|

| Arithmetic mean diameter, mm | \(D_a\) | \(D_a\boldsymbol{\ =}\frac{(a+b+c)}{3}\) | 1 | [16] |

| Geometric mean diameter, mm | \(D_g\) | \(D_g\boldsymbol{\ =}\ {(abc)}^{{1}/{3}}\) | 2 | [16] |

| Sphericity | \(\mathrm{\emptyset }\) | \(\mathrm{\emptyset }\mathrm{\ =}\frac{{(abc)}^{{1}/{3}}}{a}\) | 3 | [35] |

| Surface area, \({cm}^2\) | \(S\) | \(S=\ \pi D^2_g\) | 4 | [36] |

| Volume, \({cm}^3\) | \(V_c\) | \(V_c\mathrm{\ }=\mathrm{\ }\frac{\pi abc}{6}\) | 5 | [37] |

| Solid density, \({gcm}^{-3}\) | \({\rho }_s\) | \({\rho }_s\ =\ \frac{Mass}{volume}\) | 6 | [38] |

| Bulk density, \({gcm}^{-3}\) | \({\rho }_b\) | \({\rho }_b=\ \frac{M_b}{V_c}\) | 7 | [39] |

The solid density is the mass of individual material divided by the volume of the material. The solid density of the corncobs was determined by taking the ratio of the mass and the volume sample. A digital weighing balance (Model SF-400, ASTRECA, Surat, India) with an accuracy 0.01g was used to weigh the samples. The volume and solid density of the corncobs were computed using Eqs. (5) and (6) of Table 1.

The bulk density shows the maximum weight of a material that may be contained in an area. A container of known weight and volume was filled with corncob from a height and tapped gently and repeatedly for the samples to settle and weighed with an electronic weighing balance. Equation 7 was used to compute the bulk density of corncobs for each variety and at the corresponding moisture level.

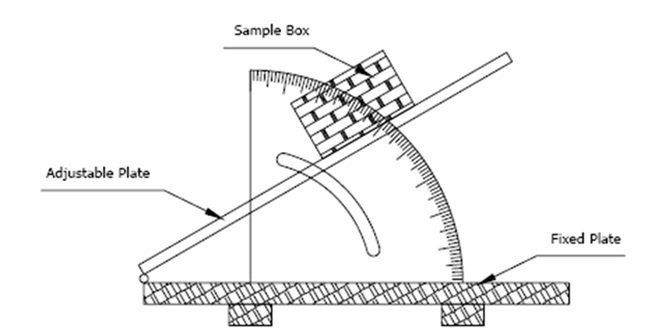

The schematic drawing of the apparatus used for determining the angle of repose of the corncobs is shown in Figure 2. Corncobs were placed on the surface of the angle of repose device. The device was raised slowly until the frictional force between the corncobs and the surface on which samples were kept was overcome by the force of gravity, and downward movement started. The angle at which the corncob starts to slide down was read from a graduated protractor attached to the device to obtain the angle of repose of the corncobs [40].

The maximum stress or force that a corncob can withstand before it breaks was also determined using UTM Universal Testing Machine (UTM) (Testometric M350-10AT, United Kingdom). The parameters used are the maximum load during a compression test and the original cross-sectional area of corncob samples. A corncob sample is placed between the UTM jaws, and a gradually increasing force is applied until the sample fractures. The UTM records the force – deformation data which is used to calculate the corncob rupture fracture strength.

Microsoft Excel software Version 2024 was used for data analyses and the relationships the corncob properties had with the varieties and moisture content were evaluated at P \(\mathrm{<}\) 0.05 levels.

The effect of moisture content on all physical and mechanical properties of corncobs from white and yellow corn varieties was significant at 5 % probability level.

The results of the axial dimensions are shown in Table 2. The values in Table 2 are mean \(\mathrm{\pm}\) standard deviation of duplicate measurements for corncobs and means with different superscripts in the same column are significantly different (p\(\mathrm{<}\)0.05).

| Variety | MC (%) | a (mm) | b (mm) | c (mm) | \(D_g\)(mm) | \(D_a\)(mm) | \(\emptyset \) |

| Yellow Corncob | 9.71 | 98.37\(^e\)\(\) | 26.89\(^j\)\(\) | 20.73\(^j\)\(\) | 37.96\(^h\)\(\) | 48.64\(^e\)\(\) | 0.50\(^b\)\(\) |

| 11.01 | 119.61\(^d\)\(\) | 28.52\(^i\)\(\) | 22.15\(^i\)\(\) | 42.28\(^e\)\(\) | 56.76\(^d\)\(\) | 0.46\(^b\)\(\) | |

| 14.29 | 120.91\(^c\)\(\) | 30.46\(^h\)\(\) | 22.97\(^h\)\(\) | 43.90\(^d\)\(\) | 58.10\(^c\)\(\) | 0.47\(^b\)\(\) | |

| 17.58 | 131.59\(^b\)\(\) | 32.08\(^g\)\(\) | 24.43\(^g\)\(\) | 46.89\(^b\)\(\) | 62.70\(^b\)\(\) | 0.47\(^b\)\(\) | |

| 21.87 | 133.27\(^a\)\(\) | 33.77\(^e\)\(\) | 24.83\(^f\)\(\) | 48.17\(^a\)\(\) | 63.95\(^a\)\(\) | 0.47\(^b\)\(\) | |

| White Corncob | 9.71 | 62.23\(^j\)\(\) | 33.63\(^f\)\(\) | 26.39\(^e\)\(\) | 38.06\(^h\)\(\) | 40.71\(^j\)\(\) | 0.63\(^a\)\(\) |

| 11.01 | 62.71\(^i\)\(\) | 34.28\(^d\)\(\) | 28.67\(^d\)\(\) | 39.50\(^g\)\(\) | 41.88\(^i\)\(\) | 0.65\(^a\)\(\) | |

| 14.29 | 65.10\(^h\)\(\) | 35.22\(^c\)\(\) | 30.23\(^c\)\(\) | 41.07\(^f\)\(\) | 43.51\(^h\)\(\) | 0.65\(^a\)\(\) | |

| 17.58 | 66.81\(^g\)\(\) | 36.46\(^b\)\(\) | 31.20\(^b\)\(\) | 42.36\(^e\)\(\) | 44.82\(^g\)\(\) | 0.65\(^a\)\(\) | |

| 21.87 | 70.09\(^f\)\(\) | 38.75\(^a\)\(\) | 31.93\(^a\)\(\) | 44.26\(^c\)\(\) | 46.92\(^f\)\(\) | 0.65\(^a\)\(\) |

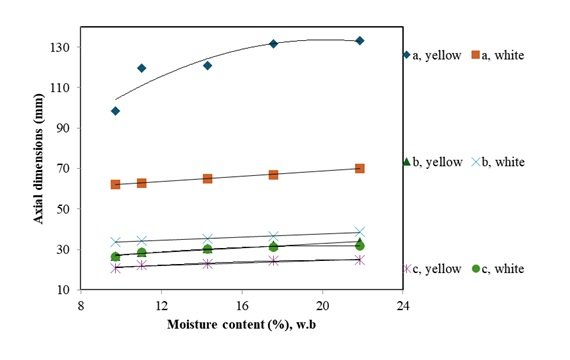

It is observed that moisture content varies with the axial dimensions of corncob of both varieties (Figure 3). The major axis of the yellow variety corncob is in the range of 98.37 to 133.27 mm and increased as moisture content rise from 9.71 to 21.87 % (Table 2).

The major axis of yellow corncob is higher than that of white corncob, and both varieties of major axes increased linearly with moisture increase. The intermediate and minor axes of yellow variety are in the range of 26.89 – 33.77 mm and 20.73 – 24.83 mm, respectively. These values are lesser than those of white variety that ranged from 33.63 – 38.75 mm and 26. 39 – 31.93 mm, respectively. The intermediate and minor axes are affected by moisture as their values increased with moisture content rise (Table 1). The relationships between moisture content and the axial dimensions are plotted in Figure 3.

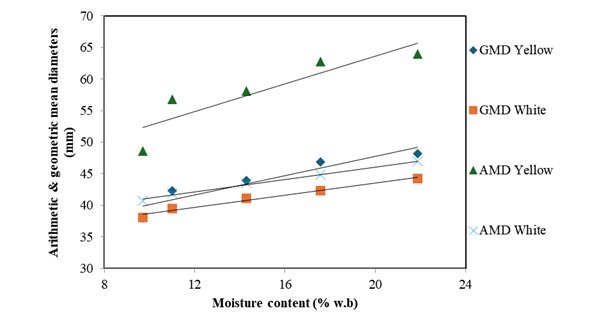

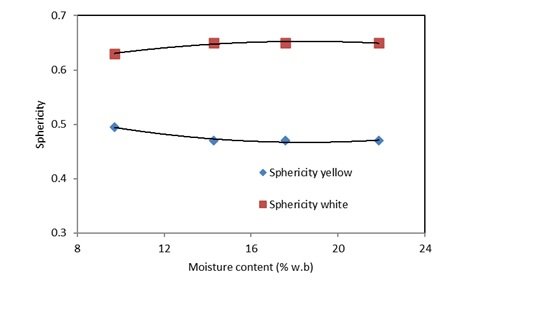

The geometric and arithmetic mean diameters of both corncob varieties increased proportionally with moisture content (Figure 4). Similar results were obtained for Indian browntop millet (Brachiaria ramosa) dimesions [30] and psyllium seeds axial dimensions [20]. The geometric and arithmetic mean diameter of corncob ranged from 37.96 to 48.17 mm and 48.64 to 63.95 mm for yellow corn and from 38.06 to 44.26 mm and 40.71 to 46.92 mm for white corn in the moisture content range of 9.71% to 21.87% w.b. (P \(\mathrm{<}\) 0.05) (Table 2). Axial dimensions are necessary to estimate the roller diameter, length and clearance [41]. To design an efficient crusher that will allow no material to pass through uncrushed, the distance between the rolls must be designed in relation to the material’s size and shape. The size of particle that is nipped in-between the roll without slippage depends on friction, distance between rolls and roll size [42]. All of these are computed using the size and friction of material to be crushed in designing a crusher. The sphericity of yellow corncob variety decreased from 0.50 – 0.47 while that of white variety increases from 0.63 to 0.65 as moisture increased (Table 2). Zewdu & Solomon [43] found the sphericity of tef seed to decrease from 0·70 to 0·63 with an increase in the moisture content from 5·6% to 21·43%. On the other hand, the increase in moisture content increased the sphericity of rapeseed [44]. The variation in sphericity of corncob varieties in relation to moisture content is one of the reasons why it is important to study each variety to understand the behaviour for efficient postharvest handling. The sphericity values that are not close to 1.0 means that corncobs will not rotate easily about any of the given axis. The effect of moisture content on corncob sphericity is shown in Figure 5.

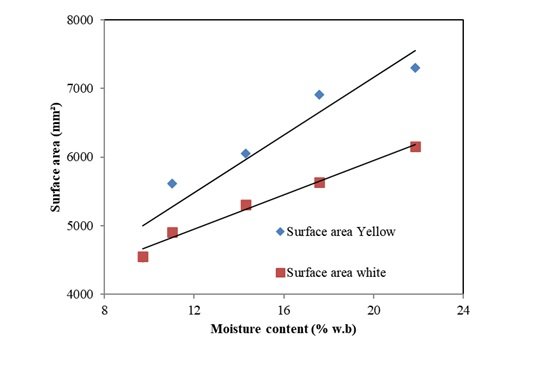

The surface area of corncob showed a significant increase with a moisture increase (Figure 6). The surface area of corncob ranged from 4532 to 7304.04 mm\({}^{2}\) and from 4551.94 to 6168.63 mm\({}^{2}\) for yellow corn and white corn, respectively.

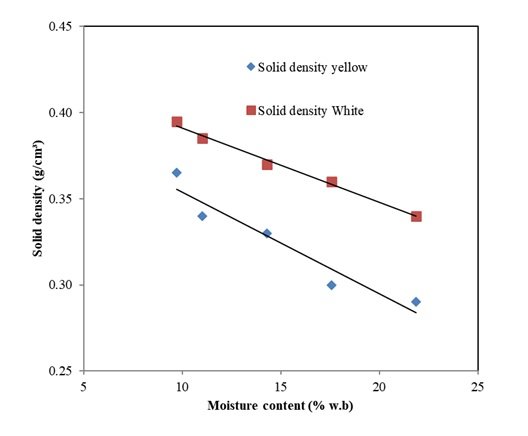

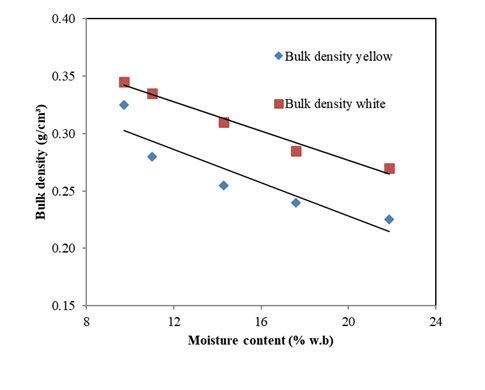

The solid density of corncobs from yellow corn at different moisture contents varied from 0.365 to 0.290 g/cm\({}^{3}\) (P \(\mathrm{<}\) 0.05); and from 0.395 to 0.340 g/cm\({}^{3}\) (P \(\mathrm{<}\) 0.05) for corncob from white corn (Figure 7). The effect of moisture content on solid density of the corncobs showed a decrease with increasing moisture content. In the same vein, corncob bulk density decreased with moisture increase. The bulk density of corncobs from yellow corn at different moisture contents varied from 0.325 to 0.225 g/cm\({}^{3}\) (P \(\mathrm{<}\) 0.05); and from 0.345 to 0.270 g/cm\({}^{3}\) (P \(\mathrm{<}\) 0.05) for corncob from white corn (Figure 8). Reduction in moisture content reduces the bulk densities of the two corncob varieties. Similar trends were observed for gram [45], wheat [46], castor [47], Brachystegia Eurycoma [48], fluted pumpkin [49], and solid biomass [50]. The bulk density decreasing as the moisture content rises indicates that the mass gain from the sample’s moisture gain is less than the volumetric expansion of the bulk that occurs concurrently [47].

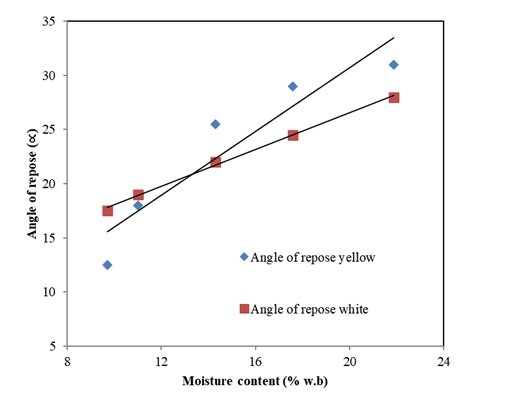

In contrast, researchers have reported an increase in bulk density with moisture content [51]. The experimental result for corncob angle of repose with respect to moisture content is shown in Figure 9. The values of the angle of repose (\(\propto\)) for the two corncobs varieties were affected by moisture content. Angel of repose of yellow variety corncob was found to increase from 12.50\(\mathrm{{}^\circ}\) to 31.00\(\mathrm{{}^\circ}\) (P \(\mathrm{<}\) 0.05) and that of white variety corncob increased from 17.50\(\mathrm{{}^\circ}\) to 28.00\(\mathrm{{}^\circ}\) (P \(\mathrm{<}\) 0.05) in the moisture range of 9.71% to 21.87% w.b.

Mirzabe et al. [52] obtained similar results for arugula seed when they investigated the engineering properties of the arugula seed needed for bulk handling and mechanical processing as a function of moisture content. The angle of repose is important for the design of containers and storage structures [53].

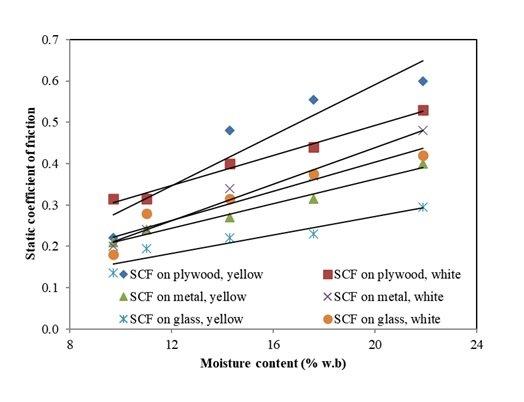

The result of static coefficients of friction of corncobs on three material surfaces (plywood, metal and glass) in relation to moisture content in the range of 9.71% to 21.87% w.b. is presented in Figure 10.

It was observed that the static coefficient of friction increased linearly with an increase in moisture content for all the three materials tested. The yellow corncob coefficient of friction increased from 0.22 – 0.60, 0.21 – 0.40 and 0.14 – 0.30 for plywood, metal and glass materials, respectively with rise in moisture content from 9.71 – 21.87% w.b. In the same vein, the coefficient of friction of white corncob variety increased from 0.32 – 0.53, 0.20 – 0.48 and 0.18 – 0.48 for plywood, metal and glass, respectively, in the moisture range of 9.71 – 21.87% w.b. At all moisture content levels, the maximum friction was offered by plywood, followed by metal and glass surface. Glass materials gave the least static coefficient of friction in all the materials studied and could be attributed to the smooth and more polished surface of glass surface compared to the other materials used. Chowdhury et al. [45] obtained similar result when they evaluated the coefficient of friction of gram using plywood, galvanized steel, celluloid sheet, and glass sheet. Their result showed that glass sheet had the lowest coefficient of static friction and plywood the highest for gram just like the result presented here for corncob coefficient of friction. The static coefficient of friction is important in selecting appropriate materials for different types of machinery, especially components requiring flow.

Coefficient of friction also finds application in the design of loading and unloading equipment, such as hoppers, and for storage systems, such as silos. The relationships between moisture content (M\({}_{c}\)) and the static coefficient of friction \((\mu )\) for plywood, metal, and glass surfaces for both corncob varieties are linear (Table 3).

| Property | Regression equation with coefficient of determination for each property | |

| Yellow corn | White corn | |

| Arithmetic mean diameter | D\(_a\)_ = 1.094M\(_c\) + 41.73 (R² = 0.801) | D\(_a\)= 0.490M\(_c\) + 36.26 (R² = 0.991) |

| Geometric mean diameter | D\(_g\)_ = 0.762M\(_c\) + 32.48 (R² = 0.878) | D\(_g\)_ = 0.482M\(_c\) + 33.85 (R² = 0.979) |

| Sphericity | \(\emptyset \) = 0.0004M\(_c\)^ \(^\ \)- 0.0133 M\(_c\) + 0.5892 (R² = 0.959) | \(\emptyset \) = -0.0003M\(_c\)^ \(^\ \)+ 0.0106 M\(_c\) + 0.5546 (R² = 0.959) |

| Surface area (mm\(^2\)) | \(S\) = 209.83M\(_c\) + 2958.3 (R² = 0.9016) | \(S\) = 125.39M\(_c\) + 3443.4 (R² = 0.9849) |

| Solid density (g/cm\(^3\)) | \(\rho _s\) = -0.0059M\(_c\) + 0.4129 (R² = 0.9257) | \(P_s\) = -0.0043M\(_c\) + 0.4343 (R² = 0.9895) |

| Bulk density (g/cm\(^3\)) | \(\rho _b\) = -0.0072M\(_c\) + 0.3726 (R² = 0.8334) | \(P_b\) = -0.0064M\(_c\) + 0.4037 (R² = 0.9765) |

| Angle of repose (\(^o\)) | \(\propto \) = 1.4691M\(_c\) + 1.3225 (R² = 0.8783) | \(\propto \) = 0.8508M\(_c\) + 9.5296 (R² = 0.997) |

| CoF on Plywood | \(\mu _pw\) = 0.030M\(_c\) – 0.021 (R² = 0.893) | \(\mu _pw\) = 0.018M\(_c\) + 0.129 (R² = 0.984) |

| CoF on Metal | \(\mu _m\) = 0.014M\(_c\) + 0.066 (R² = 0.981) | \(\mu _m\) = 0.022M\(_c\) – 0.003 (R² = 0.977) |

| CoF on Glass | \(\mu _g\) = 0.011M\(_c\) + 0.049 (R² = 0.897) | \(\mu _g\) = 0.017M\(_c\) + 0.051 (R² = 0.893) |

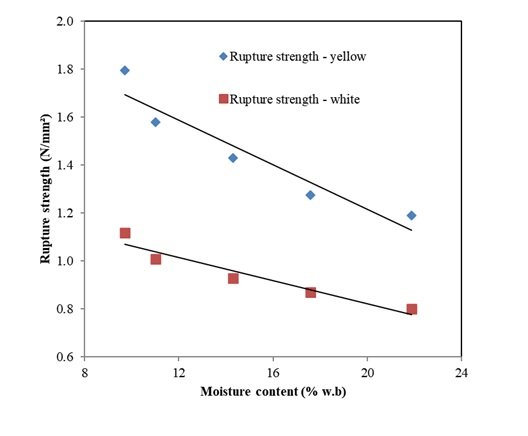

| Rupture strength (N/mm\(^2\)) | \(\gamma _r\) = -0.0465M\(_c\) + 2.1463 (R² = 0.9051) | \(\gamma _r\) = -0.024M\(_c\) + 1.3039 (R² = 0.9223) |

| M\({}_{c}\) = moisture content (%), CoF = Coefficient of friction | ||

The result of corncob rupture strength at different moisture contents is presented in Figure 11.

The rupture strength values of corncob from yellow corn were found to decrease from 1.80 N/mm\({}^{2}\) to 1.19 N/mm\({}^{2}\) and white corncob decreased from 1.12 N/mm\({}^{2}\) to 0.80 N/mm\({}^{2}\). It is observed that the rupture strength decreased as the moisture content increased from 9.71% to 21.87% w.b. The cellulose in corncob cell walls provides structure and strength, and Isa et al. [54] reported that corncob is composed of 44.9% cellulose. Moisture content affects cellulose materials because of their hydrophilic nature [55]. It has been reported that the toughness of cellulose materials decreased with rise in moisture content making it susceptible to fracture by an applied force [56]. This knowledge is vital in designing an energy efficient corncob crusher. The relationship between moisture content (M\({}_{c}\)) and rupture strength \({(\gamma }_r)\) of corncobs can be expressed using the following equations (Table 3). With these relationships established, the values of engineering properties of corncobs of yellow and white corn varieties can easily be mathematically computed once their moisture content is known. Gaining a better understanding of the moisture absorption processes and how moisture affects the properties of these cellulose materials, and their composites is crucial for improving control over these novel biomaterials [57]. The knowledge of these properties is required to design efficient agricultural materials processing equipment and machines [58, 59].

Soilless substrates enable food production in environments where traditional soil-based agriculture may not be feasible—like urban areas, deserts, or regions with degraded soils. This ensures food security and hunger reduction. In this study, the engineering properties of corncob, a cellulose and hydrophilic material, were investigated as a function of variety and moisture level. The varieties studied were from yellow and white sweet corn in the moisture range of 9.71 to 25.87%, wet basis. These properties were evaluated to obtain empirical data for designing a crushing machine for corncobs that will be used to produce soilless substrate for urban agriculture. The data obtained showed that the major, intermediate and minor axes of both corncob varieties ranged from 62.23 – 133.27 mm, 26.89 – 38.75 mm and 20.73 – 31.93 mm, respectively.

The major axis of the yellow corncob is bigger than the white corncob, whereas the intermediate and minor axis are smaller than the white corncob. All the properties investigated increased with moisture increase except the sphericity of yellow corncob, and the bulk density, rupture strength of both corncob varieties. The regression equations developed for each of the properties will be useful in calculating the properties given any moisture content value. All the empirical data determined will guide in developing an efficient crusher that will be used in producing corncob substrate. Lastly, this work promotes responsible consumption and production and facilitates efficient agricultural waste management systems that encourage a circular economy where waste becomes a resource.

Shahbandeh, M. (2024a). Grain production worldwide 2023/24, by type. Available at: https://www.statista.com/statistics/263977/world-grain-production-by-type/ (Accessed: 17 January 2025).

Hossain, F., Muthusamy, V., Bhat, J. S., Jha, S. K., Zunjare, R., Das, A., Sarika, K., & Kumar, R. (2016). Maize-Broadening the Genetic Base of Grain Cereals, Springer

Statista (2024). Consumption of corn worldwide in 2023/2024, by country (in million bushels). Available at: https://www.statista.com/statistics/691175/consumption-corn- worldwide-by-country/ (Accessed: 10 January 2025).

Dei, H. K. (2017). Assessment of maize (Zea mays) as feed resource for poultry. Poultry Science, 1, 1-32.

Ape, D. I., Nwongu, N. A., Uwakwe, E. I., & Ikedinobi, C. S. (2016). Comparative proximate analysis of maize and sorghum bought from Ogbete main market of Enugu State, Nigeria. Greener Journal of Agricultural Sciences, 6 (9), 272-375.

Shahbandeh, M. (2024b). Corn production worldwide 2023/2024, by country. Available at: https://www.statista.com/statistics/254292/global-corn-production-by- country/#statisticContainer (Accessed: 17 January 2025).

Wossen, T., Menkir, A., Alene, A., Abdoulaye, T., Ajala, S., Badu-Apraku, B., Gedil, M., Mengesha, W. & Meseka, S. (2023). Drivers of transformation of the maize sector in Nigeria. Global Food Security, 38, 100713.

Thangavelu, K., Desikan, R., Taran, O. P., & Uthandi, S. (2018). Delignification of corncob via combined hydrodynamic cavitation and enzymatic pretreatment: process optimization by response surface methodology. Biotechnology for Biofuels, 11, 1-13.

Adesanya, D. A. & Raheem, A. A. (2 009). A study of the workability and compressive strength characteristics of corn cob ash blended cement concrete. Construction and Building Materials, 23(1), 311-317.

Kaliyan, N. & Morey, R. V. (2010). Densification characteristics of corn cobs. Fuel Processing Technology, 91(5), 559-565.

Fasina, A. S., Oluwadare, D. A., Omoju, O. J., Oluleye, A. K., Ogbonnaya, U. O., & Ogunleye, K. S. (2015). Can Nigerian soils sustain crop production? – The dilemma of a soil scientist. Nature & Faune, 30(1), 34-38.

Akinola, F. F., Fasinmirin, J. T., Olanrewaju, O. O., Ewulo, B. S., & Olorunfemi, I. E. (2023). Changes in soil physical and mechanical properties under different tillage and cropping systems in alfisol soil of southwestern Nigeria. Farming System, 1(3), 100050.

Essiet, D. (2024). Addressing declining soil fertility in Africa amid population surge. Available at: https://faraafrica.org/2024/05/08/addressing-declining-soil-fertility-in- africa-amid-population-surge/ (Accessed 10 January 2025).

Okechukwu, C., Dahunsi, O. A., Oke, P. K., Oladele, I. O., Dauda, M., & Olaleye, B. M. (2017). Design and operations challenges of a single toggle jaw crusher: a review. Nigerian Journal of Technology, 36(3), 814-821.

Dickson, P. O., Ladapo, H. L., Igbozulike, A. O., & Chukwundu, K. (2023). Determination of some physical properties of African oil bean kernel relevant for design of the processing machine. Umudike Journal of Engineering and Technology, 9(1), 70-76.

Qadir, N. & Wani, I. A. (2023). Physical properties of four rice cultivars grown in Indian temperate region. Applied Food Research, 3(1), 100280.

White, N. D. G. & Jayas, D. S. (2001). Physical properties of canola and sunflower meal pellets. Canadian Biosystems Engineering, 43, 39-49.

Abedi, G., Abdollahpour, S., & Bakhtiari, M. R. (2019). The physical and mechanical properties of potato (Solanum tuberosum L.) tubers as related to the automatic separation from clods and stones. Research in Agricultural Engineering, 65(3), 77-84.

de Araujo, M. E. V., Barbosa, E. G., de Oliveira, A. C. L., Milagres, R. S., de Carvalho Pinto, F. D. A., & Corrêa, P. C. (2020). Physical properties of yellow passion fruit seeds (Passiflora edulis) during the drying process. Scientia Horticulturae, 261, 109032.

Hashemifesharaki, R. (2020). Moisture-dependent engineering characterization of psyllium seeds: physical, frictional, aerodynamic, mechanical, and thermal properties. Journal of Biosystems Engineering, 45, 374-384.

Onwe, D. N., Umani, K. C., Olosunde, W. A., & Ossom, I. S. (2020). Comparative analysis of moisture-dependent physical and mechanical properties of two varieties of African star apple (Chrysophyllum albidum) seeds relevant in engineering design. Scientific African, 8, e00303.

Pandiselvam, R., Manikantan, M. R., Kothakota, A., Rajesh, G. K., Beegum, S., Ramesh, S. V., Niral, V. & Hebbar, K. B. (2020). Engineering properties of five varieties of coconuts (Cocos nucifera L.) for efficient husk separation. Journal of Natural Fibers, 17(4), 589–597.

Vashishth, R., Semwal, A. D., Pal Murugan, M., Govind Raj, T., & Sharma, G. K. (2020). Engineering properties of horse gram (Macrotyloma uniflorum) varieties as a function of moisture content and structure of grain. Journal of Food Science and Technology, 57(4), 1477-1485.

Kruszelnicka, W., Chen, Z., & Ambrose, K. (2022). Moisture-dependent physical- mechanical properties of maize, rice, and soybeans as related to handling and processing. Materials, 15(24), 8729.

Benestante, A., Chalapud, M. C., Baümler, E., & Carrín, M. E. (2023). Physical and mechanical properties of lemon (Citrus lemon) seeds. Journal of the Saudi Society of Agricultural Sciences, 22(4), 205-213.

Wei, X., Chen, X., Liao, P., & Huang, W. (2023). Study on the mechanical properties and the way of breaking the shell of fresh Camellia oleifera fruit. Horticulturae, 9(2), 236.

Bajpai, A., Kumar, Y., Singh, H., Prabhakar, P. K., & Meghwal, M. (2020). Effect of moisture content on the engineering properties of Jamun (Syzgium cuminii) seed. Journal of Food Process Engineering, 43(2), e13325.

Shelare, S., Kumar, R., & Khope, P. (2021). Assessment of physical, frictional and aerodynamic properties of charoli (Buchanania lanzan Spreng) nut as potentials for development of processing machines. Carpathian Journal of Food Science & Technology, 13(2), 174-191.

Gierz, L., Kolankowska, E., Markowski, P., & Koszela, K. (2022). Measurements and analysis of the physical properties of cereal seeds depending on their moisture content to improve the accuracy of DEM simulation. Applied Sciences, 12(2), 549.

Kaushik, A., Saxena, D. C. & Singh, S. (2024). Engineering properties of Indian browntop millet (Brachiaria ramosa) as influenced by varietal and moisture differences. Agricultural Research, 14 78-88.

Su, Y., Cui, T., Xia, G., Gao, X., Li, Y., Qiao, M., & Xu, Y. (2021). Effects of different moisture content and varieties on physico–mechanical properties of maize kernel and pedicel. Journal of Food Process Engineering, 44(9), e13778.

Zhu, X., Chi, R., & Ma, Y. (2023). Effects of corn varieties and moisture content on mechanical properties of corn. Agronomy, 13(2), 545.

Zou, Y., Fu, J., Chen, Z., & Ren, L. (2021). The effect of microstructure on mechanical properties of corn cob. Micron, 146, 103070.

Arjun, S., Girish, G., Nagaraju, V. D., & Sridhar, B. S. (2017). Physico-fracture characteristics of Makhana (Euryale ferox) seeds. International Journal of Food Properties, 20(2), 1204-1209.

Sharma, R., Kumar, M., & Alam, M. S. (2021). Image processing techniques to estimate weight and morphological parameters for selected wheat refractions. Scientific Reports, 11(1), 20953.

Darfour, B., Ayeh, E. A., Odoi, K. M., & Mills, S. W. N. O. (2022). Physical characteristics of maize grain as influenced by varietal and moisture differences. International Journal of Food Properties, 25(1), 1351-1364.

Ehiem, J. C. & Simonyan, K. J. (2012). Physical properties of wild mango fruit and nut. International Agrophysics, 26(1), 95-98.

Asoegwu, S., Ohanyere, S., Kanu, O., & Iwueke, C. (2006). Physical properties of African oil bean seed (Pentaclethra macropylla). Agricultural Engineering International: The CIGR E. Journal, Manuscript FP 05 006. Vol. VIII, 1-16.

Sheikh, M. A., Saini, C. S., & Sharma, H. K. (2021). Computation of design-related engineering properties and fracture resistance of plum (Prunus domestica) kernels to compressive loading. Journal of Agriculture and Food Research, 3, 100101.

Ndirika, V. I. O. & Oyeleke, O. O. (2006). Determination of selected physical properties and their relationships with moisture content for millet (Pennisetum glaucum L.). Applied Engineering in Agriculture, 22(2), 291-297.

Egbe, E. A. P. & Olugboji, O. A. (2016). Design, fabrication and testing of a double roll crusher. International Journal of Engineering Trends and Technology, 35(11), 511-515.

Gupta, A. & Yan, D. (2016). Roll Crushers. Mineral Processing Design and Operations (2nd ed.). Elsevier.

Zewdu, A. D. & Solomon, W. K. (2007). Moisture-dependent physical properties of tef seed. Biosystems Engineering, 96(1), 57-63.

Izli, N. A. Z. M. I., Unal, H. A. L. I. L., & Sincik, M. E. H. M. E. T. (2009). Physical and mechanical properties of rapeseed at different moisture content. International Agrophysics, 23(2), 137-145.

Chowdhury, M. M. I., Sarker, R. I., Bala, B. K., & Hossain, M. A. (2001). Physical properties of gram as a function of moisture content. International Journal of Food Properties, 4(2), 297-310.

Tabatabaeefar, A. (2003). Moisture-dependent physical properties of wheat. International Agrophysics, 17(4), 207-211

Gharibzahedi, S. M. T, Mousavi, S. M., & Ghahderijani, M. (2011). A survey on moisture- dependent physical properties of castor seed (Ricinus communis L.). Australian Journal of Crop Science, 5(1), 1-7.

Aviara, N. A., Ibrahim, E. B., & Onuoha, L. N. (2014). Physical properties of Brachystegia Eurycoma seeds as affected by moisture content. International Journal of Agricultural and Biological Engineering, 7(1), 84-93.

Igbozulike, A. O., & Amamgbo, N. (2019). Effect of moisture content on physical properties of fluted pumpkin seeds. Journal of Biosystems Engineering, 44, 69-76.

Przywara, M., Przywara, R., Zapała, W., & Opaliński, I. (2023). Mechanical properties of solid biomass as affected by moisture content. AgriEngineering, 5(3), 1118-1135.

Igbozulike, A. O., & Aremu, A. K. (2009). Moisture dependent physical properties of Garcinia kola seeds. Journal of Agricultural Technology, 5(2), 239-248.

Mirzabe, A. H., Hajiahmad, A., & Asadollahzadeh, A. H. (2021). Moisture‐dependent engineering properties of arugula seed relevant in mechanical processing and bulk handling. Journal of Food Process Engineering, 44(6), e13704.

Mansouri, A., Mirzabe, A. H., & Raufi, A. (2017). Physical properties and mathematical modeling of melon (Cucumis melo L.) seeds and kernels. Journal of the Saudi Society of Agricultural Sciences, 16(3), 218-226.

Isa, I., Setiawati, E., Mohammad, E., & Kunusa, W. (2020). Utilization of corncob cellulose isolate (Zea mays) as adsorbent of heavy metal copper and cadmium. In IOP Conference Series: Earth and Environmental Science, 589(1), 012035.

Cichosz, S., & Masek, A. (2019). Cellulose structure and property changes indicated via wetting-drying cycles. Polymer Degradation and Stability, 167, 33-43.

Spiewak, R., Vankayalapati, G. S., Considine, J. M., Turner, K. T., & Purohit, P. K. (2022). Humidity dependence of fracture toughness of cellulose fibrous networks. Engineering Fracture Mechanics, 264, 108330.

Célino, A., Fréour, S., Jacquemin, F., & Casari, P. (2014). The hygroscopic behavior of plant fibers: a review. Frontiers in Chemistry, 1, 43.

Sulaiman, I., Egbe, E.A.P., Abdullahi, M., Saraki, Y.A., & Shehu, I.A. (2021). Design and Performance Evaluation of a Stone Crusher. UNIOSUN Journal of Engineering and Environmental Sciences, 3(2), 70- 77.

Yıldız, T., & Cevher, E. Y. (2022). Some mechanical properties of chestnut in relation to product processing and equipment design. Turkish Journal of Agriculture-Food Science and Technology, 10(8), 1565-1570.