Producing composite flour for baking requires a good understanding of the characteristics that ensures smooth processing and handling. Characteristics such as particle size, flowability, and thermal properties play a crucial role in maintaining the quality, stability, and safety of the final product. The objective of this study is to produce and evaluate the characteristics of composite flour made from 70% wheat flour and 30% sologold sweet potato flour, using a completely randomized design and standard scientific methods for analysis. The results showed that wheat flour had an average particle size of 411.16 µm, while sologold sweet potato flour had 351.97 µm. The finer particle size of the sweet potato flour makes it easier to mix and evenly blend with wheat flour. The Carr index (6.0 CL%) and Hausner ratio (1.06 HR) indicated that the composite flour had excellent free-flowing properties. The composite flour samples had moisture content ranging from 11.90% to 9.60% (dry basis). Other properties are bulk density which was between 480 and 390 kg/m³, specific heat capacity from 2.10 to 1.95 kJ/kg·K, thermal conductivity between 0.15 and 0.11 W/m·K, and thermal diffusivity from 0.09 to 0.06 m²/s. Understanding these characteristics will help ensure that the composite flour be processed efficiently while remaining stable and safe for use.

Sologold sweet potato flour (SSPF) originates from an orange-fleshed sweet potato variety renowned for its rich nutritional profile, particularly its high levels of dietary fiber, vitamins, and minerals. This variety holds great promise as an ingredient for creating composite flour blends [1]. Conversely, wheat flour remains a baking staple, prized for its ability to provide structure, texture, and flavor to baked goods [2]. However, rising price of wheat flour, its limited availability, and the absence of cost-effective alternatives have created significant challenges for Nigeria’s baking industry [3, 4]. Consequently, there is a growing demand for an accessible, affordable, and nutritionally superior substitute for wheat flour. The selection and ratio of flours in composite blends are often determined based on their distinct attributes, including particle size, flowability, and thermal properties [5, 6]. For instance, particle size distribution is a vital quality factor in wheat flour, influencing its functionality, texture, structure, and the processing of baked products [2, 7].

Thermal properties are equally important in baking, influencing how composite flours behave under heat. Understanding these properties aids in optimizing baking conditions, facilitating the transfer of heat, achieving desirable textures and flavors [8, 9]. Key factors affecting thermal properties include moisture content, bulk density, specific heat, and thermal diffusivity [10, 11]. Another critical characteristic is flowability, which refers to the ability of flour or powder to move smoothly and consistently, impacting processes such as mixing, transportation, and packaging [12]. This study aims to produce and evaluate composite flour made from wheat and sologold sweet potato, focusing on particle size, flowability, and thermal properties to assess its suitability for baking applications.

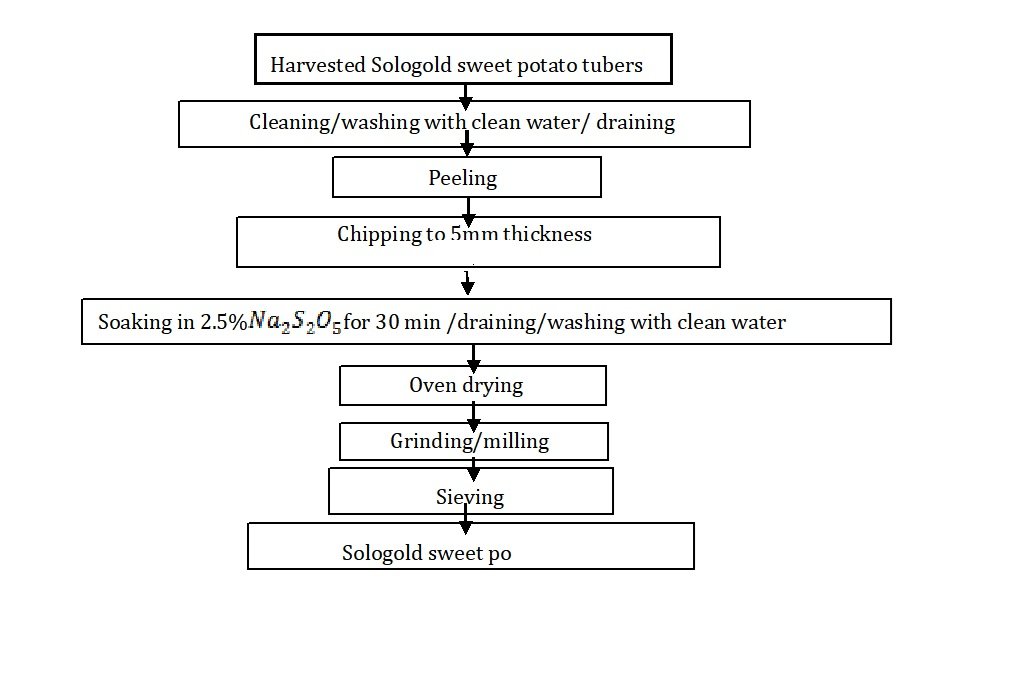

Ten kilograms (10kg) of sologold sweet potatoes was taken from the two hundred kilograms (200kg) obtained for this research work. The fresh sologold sweet potato tubers was washed thoroughly, drained and peeled. With the initial properties of the fresh sologold sweet potato determined, the tubers was chopped to chips of 5mm thickness and then soaked in 2.5% Sodium Metabisulphate for 30 minutes. The pre-treated sologold potato chips was drained and divided to One hundred and Fifty grams (150g) each. The samples were then be dried in hot air oven set at temperature of 550C for 18hours until constant weights were obtained in three consecutive reading. The dried chips were crushed and milled with cyclone mill into flour. The milled flour was sieved and a fine flour with uniform particle size obtained. The detailed flow chart for the production of sologold sweet potato flour is as presented in Figure 1.

The study design used was completely randomized design (CRD) with A1= Wheat flour (100%), Sologold sweet potato flour (0%); B1= Wheat flour (90%), Sologold sweet potato flour (10%); B2= Wheat flour (80%), Sologold sweet potato flour (20%); B3= Wheat flour (70%), Sologold sweet potato flour (30%); B4= Wheat flour (60%), Sologold sweet potato flour (40%) and B5= Wheat flour (50%), Sologold sweet potato flour (50%) Which is shown in Table 1.

| Samples | Flour Blend Ratio | Sologold-sweet potato flour (g) | Wheat flour (g) |

| A1 | 100% Wheat flour, 0% Sologold sweet potato flour | 0 | 300 |

| B1 | 90% Wheat flour, 10% Sologold sweet potato flour | 30 | 270 |

| B2 | 80% Wheat flour, 20% Sologold sweet potato flour | 60 | 240 |

| B3 | 70% Wheat flour, 30% Sologold sweet potato flour | 90 | 210 |

| B4 | 60% Wheat flour, 40% Sologold sweet potato flour | 120 | 180 |

| B5 | 50% Wheat flour, 50% Sologold sweet potato flour | 150 | 150 |

| B6 | 40% Wheat flour, 60% Sologold sweet potato flour | 180 | 120 |

| B7 | 30% Wheat flour, 70% Sologold sweet potato flour | 210 | 90 |

| B8 | 20% Wheat flour, 80% Sologold sweet potato flour | 240 | 60 |

| B9 | 10% Wheat flour, 90% Sologold sweet potato flour | 270 | 30 |

| A2 | 0% Wheat flour, 100% Sologold sweet potato flour | 300 | 0 |

The Sologold sweet potatoes were obtained from the National Root Crops Research Institute in Umudike, while the wheat flour (Dangote brand) was purchased from Urugba Market, Umuahia. Key equipment included a hammer mill (75KW 65X75 Wood), automatic sieve shaker (ASM 400-Siebtechnic), flour calorimeter (CAL3K-AP), electronic weighing balance (FA604G Hellog), stopwatch (Casio AE-504), electronic dough mixer (130L Sokany), volumetric flasks (Class A- ASTM), and various bowls.

The study design used was completely randomized design (CRD) with A1= Wheat flour (100%), SSPF (0%); B1= Wheat flour (90%), SSPF (10%); B2= Wheat flour (80%), SSPF (20%); B3= Wheat flour (70%), SSPF (30%); B4= Wheat flour (60%), SSPF (40%), B5= Wheat flour (50%), SSPF (50%), B6= Wheat flour (40%), SSPF (60%), B7= Wheat flour (30%), SSPF (70%), B8= Wheat flour (20%), SSPF (80%), B9= Wheat flour (10%), SSPF (90%) and A2= Wheat flour (0%), SSPF (100%).

Particle size distribution was measured using sieve analysis, following the method by Li et al. [13]. Flour samples (50g) were placed on sieves with decreasing aperture sizes (150, 60, 44, 22, and 10 µm) arranged from top to bottom. The retained flour on each sieve was weighed and calculated as a percentage of the total weight. Standard formulas were used to determine cumulative passing percentages and average particle diameters.

Flowability was assessed using bulk density, tapped density, Carr index, and Hausner ratio, following [14] methods. Bulk density was calculated as the ratio of flour weight to untapped volume, while tapped density was determined after 500 taps. Lower Carr index and Hausner ratio values indicated better flowability. The angle of repose (\(\theta\)R) was also measured to further assess flowability.

Thermal properties, including heat capacity, thermal conductivity, and thermal diffusivity, were evaluated using [15] methods. Specific equations were applied to calculate each property, and results demonstrated how moisture content and bulk density influenced heat transfer efficiency.

(i) The heat capacity \(C_p\) is given as [16]: \[C_p = C_w W_w (T_e – T_w) – C_{ca} W_{ca} (T_{ca} – T_e) / W_s (T_s – T_e), \tag{1}\] where, \(C_p\) is specific heat of the sample (KJ/KgK), \(C_w\) is specific heat of water (KJ/KgK), \(C_{ca}\) is specific heat of the capsule (KJ/KgK), \(W_w\) is mass of water in the calorimeter (kg), \(W_{ca}\) is mass of the capsule (kg), \(W_s\) is mass of the sample (kg), \(T_{ca}\) is initial temperature of the capsule containing the sample (K), \(T_e\) is equilibrium temperature of the mixture (K), \(T_w\) is initial temperature of water in the calorimeter (K) and \(T_s\) is initial temperature of the sample (K).

(ii) Thermal conductivity (\(K\)) is given as [16]: \[K = \frac{VI \ln (t_2/t_1)}{4 \pi l (T_2 – T_1)}, \tag{2}\] where, \(K\) = Thermal conductivity, \(V\) = Voltage (V), \(I\) = Current, \(t_1\) = Initial time (s), \(t_2\) = Final time (s), \(T_1\) = Initial temperature (\(^\circ\)C) and \(T_2\) = Final temperature (\(^\circ\)C)

(iii) Thermal diffusivity (\(\alpha\)) is given as [16]: \[\alpha = \frac{h}{c \rho}, \tag{3}\] where, \(\alpha\) is thermal diffusivity (m\(^2\)s\(^{-1}\)), \(h\) is thermal conductivity (Wm\(^{-1}\)K\(^{-1}\)), \(c\) is specific heat (KJKg\(^{-1}\)K\(^{-1}\)) and \(\rho\) is bulk density (Kgm\(^{-3}\)).

The AMD (arithmetic mean diameter) and PF (percent finer) of wheat flour and sologold sweet potato flour are shown in Table 2.

| S/N | Time (Mins) | Wheat Flour (WF) | Sologold sweet potato flour (SSPF) | ||

|---|---|---|---|---|---|

| Dav | % Finer | Dav | % Finer | ||

| 1 | 8 | 393.42 | 96 | 412.88 | 90 |

| 2 | 10 | 414.23 | 98 | 354.13 | 96 |

| 3 | 12 | 347.77 | 98 | 374.67 | 94 |

| 4 | 14 | 434.82 | 96 | 366.82 | 94 |

| 5 | 16 | 414.28 | 96 | 294.75 | 96 |

| 6 | 18 | 462.42 | 96 | 308.55 | 96 |

The particle size analysis revealed that wheat flour had a mean particle diameter of 411.16 µm, while SSP flour measured 351.97 µm. The smaller particle size of SSP flour contributed to better mixing with wheat flour, resulting in a more consistent composite blend. This improved texture, hydration, and flowability, making the flour suitable for baking applications [15, 17].

The flowability property of the samples were determined by the characteristics as shown in Table 3.

| Samples | W: SSP (g) | Bulk Density (Kg/m\(^3\)) | Tapped Density (Kg/m\(^3\)) | Angle of Repose OR | Carr Index CL% | HausnerRatio HR | Flowability Behaviour |

| A1 | 100:0 | 500\(\mathrm{\pm}\)4.5\(^a\) | 530\(\mathrm{\pm}\)4.2\(^b\) | 34.0\(\mathrm{\pm}\)2.5\(^a\) | 09 | 1.06 | Free flowing |

| B1 | 90:10 | 480\(\mathrm{\pm}\)4.0\(^b\) | 512\(\mathrm{\pm}\)4.6\(^b\) | 32.5\(\mathrm{\pm}\)2.0\(^a\) | 11 | 1.07 | Free flowing |

| B2 | 80:20 | 460\(\mathrm{\pm}\)4.6\(^bc\) | 495\(\mathrm{\pm}\)4.2\(^b\) | 31.5\(\mathrm{\pm}\)2.2\(^a\) | 07 | 1.07 | Free flowing |

| B3 | 70:30 | 450\(\mathrm{\pm}\)3.6\(^bc\) | 480\(\mathrm{\pm}\)4.5\(^b\) | 30.0\(\mathrm{\pm}\)1.0\(^a\) | 06 | 1.06 | Free flowing |

| B4 | 60:40 | 440\(\mathrm{\pm}\)2.5\(^bc\) | 465\(\mathrm{\pm}\)4.0\(^c\) | 28.5\(\mathrm{\pm}\)2.0\(^ab\) | 05 | 1.05 | Free flowing |

| B5 | 50:50 | 430\(\mathrm{\pm}\)3.2\(^bc\) | 450\(\mathrm{\pm}\)3.5\(^c\) | 28.0\(\mathrm{\pm}\)1.0\(^ab\) | 04 | 1.04 | Free flowing |

| B6 | 40:60 | 420\(\mathrm{\pm}\)4.0\(^c\) | 440\(\mathrm{\pm}\)4.6\(^c\) | 27.0\(\mathrm{\pm}\)1.5\(^ab\) | 04 | 1.05 | Free flowing |

| B7 | 30:70 | 410\(\mathrm{\pm}\)3.5\(^c\) | 432\(\mathrm{\pm}\)4.0\(^c\) | 26.0\(\mathrm{\pm}\)0.5\(^b\) | 11 | 1.05 | Free flowing |

| B8 | 20:80 | 400\(\mathrm{\pm}\)2.8\(^c\) | 425\(\mathrm{\pm}\)3.5\(^a\) | 25.4\(\mathrm{\pm}\)1.2\(^b\) | 10 | 1.06 | Free flowing |

| B9 | 10:90 | 390\(\mathrm{\pm}\)2.5\(^c\) | 430\(\mathrm{\pm}\)3.0\(^a\) | 24.5\(\mathrm{\pm}\)2.0\(^b\) | 09 | 1.10 | Free flowing |

| A2 | 0:100 | 380\(\mathrm{\pm}\)3.0\(^c\) | 415\(\mathrm{\pm}\)2.5\(^a\) | 23.0\(\mathrm{\pm}\)1.0\(^b\) | 08 | 1.09 | Free flowing |

Value followed by same superscript alphabet are not significantly different at (P\(\mathrm{<}\)0.05) along the column. Values are Mean \(\mathrm{\pm}\) SEM of triplicate determination.

All composite flour samples exhibited angles of repose below 32.5\(\mathrm{{}^\circ}\), classifying them as free-flowing. The Carr index ranged from 11.0% to 4.0%, and the Hausner ratio varied between 1.10 and 1.04, confirming excellent flowability across all blends. A sample with superior flowability characteristics inevitably supports efficient handling and baking [15, 18].

Flour thermal properties are vital for the various heat transfer processes during baking [19]. The thermal properties of composite flour samples is shown in Table 4.

Value followed by same superscript alphabet are not significantly different at (P\(\mathrm{<}\)0.05) along the column. Values are Mean \(\mathrm{\pm}\) SEM of triplicate determination.

Thermal properties, such as heat capacity, thermal conductivity, and thermal diffusivity, were influenced by moisture content and bulk density. Specific heat capacity values ranged from 2.10 to 1.95 KJKg\(^{-1}\)K\(^{-1}\), thermal conductivity ranged from 0.15 to 0.11 Wm\(^{-1}\)K\(^{-1}\), and thermal diffusivity ranged from 0.09 to 0.06 m²s\(^{-1}\). Higher moisture content enhanced thermal conductivity and diffusivity, facilitating effective heat transfer during baking. From Table 4, increase in moisture content reflects an increase in thermal conductivity and thermal diffusivity. Thermal conductivity of the samples range from 0.15 to 0.10 while thermal diffusivity from 0.10 to 0.05. The values obtained showed low thermal conductivity and diffusivity which suggest an effective heat transfer in the composite flour samples [20, 21].

| Sample | Moisture content (%db) | Bulk density (kg m\(^-3\)) | Specific heat (KJKg\(^-1\)K\(^-1\)) | Thermal conductivity (Wm\(^-1\)K\(^-1\)) | Thermal diffusivity (m\(^2\)s\(^-1\)) |

| A1 | 12.02\(\mathrm{\pm}\)0.8\(^c\) | 500\(\mathrm{\pm}\)4.5\(^a\) | 1.90 | 0.15 | 0.10 |

| B1 | 11.90\(\mathrm{\pm}\)1.0\(^c\) | 480\(\mathrm{\pm}\)4.0\(^b\) | 2.05 | 0.15 | 0.09 |

| B2 | 11.86\(\mathrm{\pm}\)1.5\(^c\) | 460\(\mathrm{\pm}\)4.6\(^c\) | 2.07 | 0.14 | 0.09 |

| B3 | 11.14\(\mathrm{\pm}\)1.4\(^c\) | 450\(\mathrm{\pm}\)3.6\(^c\) | 2.10 | 0.14 | 0.08 |

| B4 | 10.54\(\mathrm{\pm}\)1.2\(^c\) | 440\(\mathrm{\pm}\)2.5\(^c\) | 2.09 | 0.14 | 0.08 |

| B5 | 10.35\(\mathrm{\pm}\)1.5\(^c\) | 430\(\mathrm{\pm}\)3.2\(^c\) | 1.95 | 0.13 | 0.08 |

| B6 | 10.12\(\mathrm{\pm}\)1.6\(^c\) | 420\(\mathrm{\pm}\)4.0\(^c\) | 2.08 | 0.13 | 0.07 |

| B7 | 9.83\(\mathrm{\pm}\)0.5b\(^c\) | 410\(\mathrm{\pm}\)3.5\(^c\) | 2.02 | 0.12 | 0.07 |

| B8 | 9.74\(\mathrm{\pm}\)1.0b\(^c\) | 400\(\mathrm{\pm}\)2.8\(^c\) | 2.04 | 0.12 | 0.07 |

| B9 | 9.60\(\mathrm{\pm}\)1.2b\(^c\) | 390\(\mathrm{\pm}\)2.5\(^c\) | 2.01 | 0.11 | 0.06 |

| A2 | 9.52\(\mathrm{\pm}\)0.8b\(^c\) | 380\(\mathrm{\pm}\)3.0\(^c\) | 2.06 | 0.10 | 0.05 |

The ANOVA (Table 4) shows that there is no significant difference (p\(\mathrm{>}\) 0.05) in the thermal properties of the composite flour samples.

| Composition | Sum of Squares | Df. | Mean Square | F | Sig. | |

| MC | Between Groups | 102.82346 | 3 | 1.52846 | 2.34812 | 1.072 |

| Within Groups | .014 | 1 | .004 | |||

| Total | 4 | |||||

| BD | Between Groups | 220.9374 | 20 | 5.82744 | 5.06271 | 1.091 |

| Within Groups | .032 | 1 | .003 | |||

| Total | 21 | |||||

| SH | Between Groups | 2.8402 | 2 | 0.01371 | 1.65828 | 0.320 |

| Within Groups | .010 | 1 | .002 | |||

| Total | 3 | |||||

| TC | Between Groups | 2.7721 | 3 | 0.02193 | 1.29374 | 0.708 |

| Within Groups | 1.21 | 1 | .003 | |||

| Total | 4 | |||||

| TD | Between Groups | 1.2216 | 1 | 0.048441 | 2.18032 | 0.214 |

| Within Groups | 0.25 | 2 | .002 | |||

| Total | 3 | |||||

|

MC: Moisture content BD: Bulk density SH: Specific heat

TC: Thermal conductivity TD: Thermal diffusivity |

||||||

In conclusion, the characterization of the samples show that:

(i) SSP flour’s smaller particle size allowed for uniform mixing with wheat flour, creating consistent composite blends.

(ii) All blends demonstrated excellent flowability, as indicated by Carr index and Hausner ratio values.

(iii) The thermal properties of the composite flours supported efficient heat transfer, crucial for producing high-quality baked goods.

(iv) 70% wheat flour, 30% SSP flour emerged as the optimal formulation for stable, high-quality baked products, balancing particle size, flowability, and thermal characteristics.

The motorized ginger juice expression machine is recommended for large-scale ginger juice expression in rural and urban communities. Further experimental tests such as performance evaluation could be carried out on the ginger juice expression machine.

Oloniyo, R. O., Omoba, O. S., Awolu, O. O., & Olagunju, A. I. (2021). Orange‐fleshed sweet potatoes composite bread: A good carrier of beta (\(\beta\))‐carotene and antioxidant properties. Journal of Food Biochemistry, 45(3), e13423.

Wanjuu, C., Abong, G., Mbogo, D., Heck, S., Low, J., & Muzhingi, T. (2018). The physiochemical properties and shelf‐life of orange‐fleshed sweet potato puree composite bread. Food Science & Nutrition, 6(6), 1555-1563.

Edema, M. O., Sanni, L. O., & Sanni, A. I. (2005). Evaluation of maize-soybean flour blends for sour maize bread production in Nigeria. African Journal of Biotechnology, 4(9), 911-918.

Olaoye, O. A., Onilude, A. A., & Idowu, O. A. (2006). Quality characteristics of bread produced from composite flours of wheat, plantain and soybeans. African journal of Biotechnology, 5(11), 1102-1106.

Giami, S. Y. (2004). Comparison of bread making properties of composite flour from kernels of roasted and boiled African bread fruit (Treculia Africana decne) seeds. Journal of Materials Research, 1(1), 16-25.

Devani, B. M., Jani, B. L., Kapopara, M. B., Vyas, D. M., & Ningthoujam, M. D. (2016). Study on quality of white bread enriched with finger millet flour. International Journal of Agriculture, Environment and Biotechnology, 9(5), 903.

Pycia, K., & Ivanišová, E. (2020). Physicochemical and antioxidant properties of wheat bread enriched with hazelnuts and walnuts. Foods, 9(8), 1081-1113.

Rateesh Krishnan, R. K., Usha Dharmaraj, U. D., Manohar, R. S., & Malleshi, N. G. (2011). Quality characteristics of biscuits prepared from finger millet seed coat based composite flour. Food Chemistry, 129, 499-506.

Lakshmi Menon, L. M., Majumdar, S. D., & Usha Ravi, U. R. (2014). Mango (Mangifera indica L.) kernel flour as a potential ingredient in the development of composite flour bread. Indian Journal of Natural Products and Resources, 5(1), 75-82.

Falola, A. O., Olatidoye, O. P., Balogun, I. O., & Opeifa, A. O. (2013). Evaluation of nutritional, physicochemical properties and acceptability of un-dehulled’ofada’rice and soy bean flour blends. Journal of Agriculture and Veterinary Science, 5, 118-128.

Aziz, A. A., Padzil, A. M., & Muhamad, I. I. (2018). Effect of incorporating purple-fleshed sweet potato in biscuit on antioxidant content, antioxidant capacity and colour characteristics. Malaysian Journal of Analytical Sciences, 22(4), 667-675.

Obeta, N. A. (2016). Quality characteristics of breads fortified with sesame seed. Global Journal of Medical Research, 16(L2), 21-26.

Li, Q. M., Li, Y., Zou, J. H., Guo, S. Y., Wang, F., Yu, P., & Su, X. J. (2020). Influence of adding Chinese yam (Dioscorea opposita Thunb.) flour on dough rheology, gluten structure, baking performance, and antioxidant properties of bread. Foods, 9(3), 256–315.

Association of Official Analytical Chemists. (2000). Official Methods of Analysis of the Association of Official Analytical Chemists (Vol. 11). The Association.

Hanim, A. M., Chin, N. L., & Yusof, Y. A. (2014). Physico-chemical and flowability characteristics of a new variety of Malaysian sweet potato, VitAto Flour. International Food Research Journal, 21(5), 2099.

Tosin, P., Adebisi, O. W., & Okon, A. O. (2024). Evaluation of particle size, flowability and thermal properties of formulated composite wheat-sologold sweet potato flour for baked products. International Journal of Physical Sciences, 18(1), 18-25.

Chuango, K., Julianti, E., & Ginting, S. (2019, May). Effect of pre-treatment in the making of purple-fleshed sweet potato flour towards cake characteristics. In IOP Conference Series: Earth and Environmental Science (Vol. 260, No. 1, p. 012090). IOP Publishing.

Etti, C. J., Yusof, Y. A., Chang, L. S., & Ekanem, V. G. (2019). Flowability and physical properties of wheat-unripe plantain composite flour. Food Research, 3(2): 151-156.

Selvakumaran, L., Shukri, R., Ramli, N. S., Dek, M. S. P., & Ibadullah, W. Z. W. (2019). Orange sweet potato (Ipomoea batatas) puree improved physicochemical properties and sensory acceptance of brownies. Journal of the Saudi Society of Agricultural Sciences, 18(3), 332-336.

Shimelis, E. A., Meaza, M., & Rakshit, S. (2006). Physico-chemical properties, pasting behavior and functional characteristics of flours and starches from improved bean (Phaseolus Vulgaris L.) varieties grown in East Africa. CIGR Ejournal, 8, 1-18.

Olosunde, W. A., Paul, T., & Antia, O. O. (2023). Formulation of an improved nutritional quality composite flour for bakery products using wheat and sologold sweet potato. American Journal of food science and technology (AJFST), 2(2), 37-45.